Oemeta cooling lubricants are used successfully in a wide range of industries.

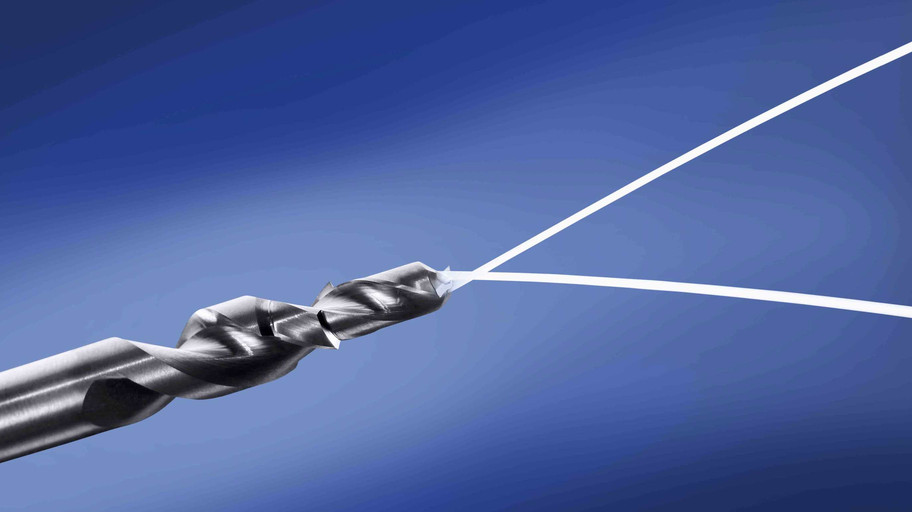

A wide variety of cooling lubricants are in demand in machining production. When it comes to drilling, milling, turning and grinding, things get hot. Oemeta cooling lubricants ensure the necessary cooling – and they make sure every machine keeps running. Whether steel, aluminium, ceramics, glass or titanium: thanks to our industry experience, we are able to offer you the lubricants that meet your specific requirements and ensure greater productivity.

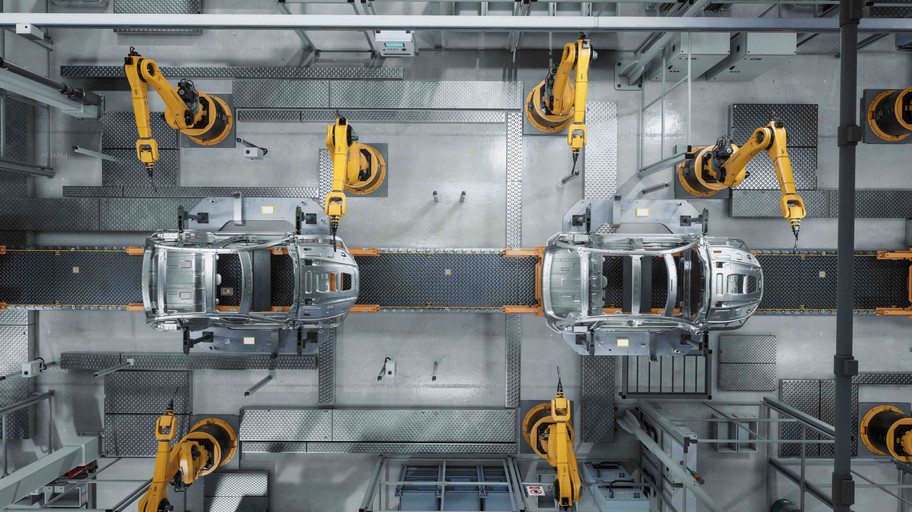

Automotive industry

Aerospace

E-mobility

Medical technology

In the manufacture of electronics and semiconductors, it is vital to avoid contamination of the devices so as to ensure a high level of accuracy and durability. The wide-ranging Oemeta cooling lubricant portfolio is sure to include the right product for your application.

Whether optical lenses or ceramic hobs: in glass processing, grinding has to be as residue-free as possible. In addition, a high flushing capacity is required for effective removal of the micro-particles. Our oil-free cooling lubricants are the number one choice here. They leave no marks on the glass – and your product can be coated without any problems.

In mechanical engineering, versatility and flexibility are crucial. This is because different metals are often processed in the production process – from steel and aluminium to brass and copper. The cooling lubricants used must have all-round capabilities that guarantee maximum performance in every material machining operation. That is why our products are designed for a wide range of applications.